Marek Grzybowski (5) questions to Dorota Lost Sieminska, Director, Legal Affairs and External Relations Division, IMO

An Exclusive interview to Baltic Journalist Maritime Club of the Baltic Sea & Space Cluster (BSSC)

The leading topic of the meeting was the role of women in world administration, science and maritime business during the WISTA Poland meeting.

– Ladies work in all areas related to the 17 IMO Sustainable Development Goals – Dorota Lost Sieminska, Director, Legal Affairs and External Relations Division, IMO emphasized during the meeting.

We asked Director Dorota Lost Sieminska about the role and tasks of the Legal Affairs and External Relations Division of the IMO in activities for the development of safety in maritime transport, activities for sustainable development and other factors ensuring the functioning of people at sea.

Marek Grzybowski: Please, describe the fields in which the Legal Affairs and External Relations Division, IMO operates?

Dorota Lost Sieminska, Director, Legal Affairs and External Relations Division, IMO:

Role of the Legal Affairs and External Relations Division

The Legal Affairs and External Relations Division consists of four offices: the Legal Affairs Office (LAO), the External Relations Office (ERO), the Public Information Services (PIS) and the Maritime Knowledge Centre (MKC).

Legal Affairs Office

LAO is responsible for providing legal advice on a wide range of issues related to the activities of the Organization. LAO protects the legal interests of IMO by advising the Secretary-General, the treaty-making bodies, the Member States and other Divisions of the Secretariat. LAO is responsible for reviewing the contractual activities of IMO, including agreements with private and non-state organizations such as banks and goods and services providers. The Office also assists with the negotiation and conclusion of Host Government Agreements for meetings and activities held by IMO in other countries.

LAO is responsible for legal advice on questions of related to the Convention on the International Maritime Organization and other treaties adopted under the auspices of the Organization and provides legal support at all stages of the amendment process. The Secretary-General of IMO is the depositary for more than 50 treaties. In this context, LAO examines instruments of accession, ratification, acceptance, etc. related to IMO treaties deposited by Governments and any associated reservations or declarations. LAO reports to the Assembly and to the Council on the status of the IMO Convention, as well as on the status of all treaties adopted at IMO.

Furthermore, LAO is responsible for the IMO Legal Committee and provides legal advice to the Assembly, the Council, diplomatic conferences, and various other committees. The Office also assists Human Resources Services on legal aspects of personnel issues. Additionally, LAO is responsible for protecting IMO’s intellectual property rights.

External Relations Office

ERO is responsible for providing protocol support to meetings and events involving the Secretary-General, both at and away from Headquarters, as well as visits of high-level dignitaries to the IMO. The Office acts as the liaison between the Permanent Missions and the Government of the United Kingdom of Great Britain and Northern Ireland for the purpose of facilitating and ensuring the proper accreditation of the members of the missions to IMO. ERO is in charge of assisting in the presentation of credentials to the Secretary-General by newly appointed Permanent Representatives, as well as organising events hosted by the Secretary-General.

In addition to arranging flag-raising and ensuring the observance of official periods of mourning, ERO is responsible for maintaining up-to-date lists of Heads of Diplomatic Missions, Permanent Missions, Focal points, Liaison Officers as well as Intergovernmental and Nongovernmental Organizations which have observer status with IMO. ERO is also in charge of the events related to the World Maritime Theme.

Public Information Services

PIS provides strategic and hands-on communication and outreach support for all IMO’s work and initiatives. PIS is engaged in a multitude of connected and integrated outreach activities designed to improve global awareness of the Organization and its impact, through storytelling on multiple integrated platforms. These include the news and hot topic sections of the IMO public website (in English, French and Spanish); issuing press releases;, arranging press conferences and television/radio interviews, responding to media requests, in-house production of multimedia digital content including videos, and giving presentations on the work of IMO to groups visiting the Organization. PIS provides summary reports of and provides media support to all IMO meetings.

PIS leads the annual Day of the Seafarer campaign (25 June) and promotes the International Day for Women in Maritime (18 May) and the World Maritime theme each year.

Maritime Knowledge Centre

The MKC provides collections, information resources and services to support the IMO Secretariat, Member States, representatives and delegates. Its specialized collections comprise the archives of official documents and IMO Publications, including IMO Conventions, meeting summaries, piracy reports, research guides, and a facts and figures page. The MKC also collects resources covering maritime affairs, shipping and other subjects relevant to the work of the Organization.

Additionally, the MKC runs a Current Awareness Bulletin that provides a monthly digest centred around topics and themes related to the work of IMO. The Bulletin is free to download and to distribute.

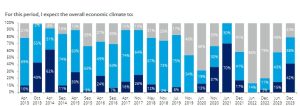

Marek Grzybowski: The maritime business situation has changed dramatically after the Covid-19 pandemic. How are the IMO doing in this situation?

Dorota Lost Sieminska, Director, Legal Affairs and External Relations Division, IMO:

Indeed, the COVID-19 pandemic changed the world in many aspects. At the beginning of 2020, IMO had to adjust to the new working methods, at the same time addressing the challenges faced by the shipping sector.

Throughout the pandemic, the maritime sector has continued to deliver the vital supplies that people need. Seafarers have worked tirelessly, at the heart of this trade, to keep goods flowing. Despite difficulties with port access, repatriation, crew changes and more, there can be no denying that seafarers have gone beyond the call of duty.

The Secretary-General of IMO worked with Governments, shipowners and relevant United Nations organizations to ensure that seafarers get all the necessary support. One of the major achievements was the adoption of the United Nations Assembly resolution calling on UN Member States to designate seafarers and other marine personnel as key workers and to implement relevant measures to allow stranded seafarers to be repatriated and others to join ships, and to ensure access to medical care. The Secretary-General also urged the Governments to prioritize seafarers in their national COVID-19 vaccination programmes.

The United Nations bodies and agencies issued a large range of recommendations, including key legal, policy and technical guidance, as well as joint statements and declarations to address the challenges posed by the pandemic to the transport industry, and have highlighted that additional, country-level concrete means of action are needed to tackle them,

IMO continues to work with our sister UN agencies, with industry bodies and with Governments to address the ongoing needs of seafarers.

The Joint Action Group has been established to review the impact of the COVID-19 pandemic on the world’s transport workers and the global supply chain (JAG-TSC), consisting of representatives of ICAO, ILO, IMO, WHO, the International Air Transport Association (IATA), the International Chamber of Shipping (ICS), the International Organization of Employers (IOE), the International Road Transport Union (IRU), the International Transport Workers’ Federation (ITF) and International Union of Railways (UIC). The Group discussed serious and urgent challenges faced by transport workers resulting from the COVID-19 pandemic.

As a result of this cooperation, the IMO Assembly, which met at its 33rd session from 27 November to 7 December this year, adopted resolution A.1189(33) on the recommendations emanating from the Joint Action Group to review the impact of the COVID-19 pandemic on the world’s transport workers and the global supply chain (JAG-TSC).

Marek Grzybowski: Russia’s attack on Ukraine creates new challenges for the global maritime business. What was IMO’s response to this situation?

Dorota Lost Sieminska, Director, Legal Affairs and External Relations Division, IMO:

The IMO Council, which met on 10 and 11 March 2022, at its thirty-fifth extraordinary session, requested the IMO committees to consider ways to enhance the efforts of Member States and observer organizations in supporting affected seafarers and commercial vessels and consider the implications of the situation in the Black Sea for the implementation of IMO treaties.

Through 2022-2023, IMO organs such as the Council, the Legal Committee, the Maritime Safety Committee, the Facilitation Committee, the Marine Environment Protection Committee and Technical Cooperation Committee) have reviewed and condemned Russia Federation’s actions and called on the Russian Federation to withdraw from Ukraine.

The IMO Assembly, at its 33rd session in December this year, discussed the ongoing conflict in Ukraine. The Assembly adopted several resolutions, among them resolution A.1183(33) on the impact of the Russian armed invasion of Ukraine on international shipping.

Marek Grzybowski: The role of women in the maritime logistics business is growing. WISTA International, Anglo-Eastern Ship Management, the International Seafarers Welfare Assistance Network (ISWAN) and the International Chamber of Shipping (ICS) conducted an online survey to find out how seafarers perceive ‘discrimination’ and how on board based on their personal experiences. As many as 60% of women reported that they faced gender discrimination on board. 66% of respondents report that their employees have started harassing and intimidating co-workers. 25% of female shipboarders said that in the maritime transport sector, physical and sexual harassment is widespread, occurs on board and is an invasion of their privacy. International Day for Women in Maritime 2023 theme was ”Mobilizing networks for gender equality”. What actions need to be mobilized for gender equality?

Dorota Lost Sieminska, Director, Legal Affairs and External Relations Division, IMO:

As we know, the shipping industry is traditionally male dominated. In this context, in 1988 IMO initiated a gender programme to help the industry to be more inclusive and to support women to achieve a representation that is adequate in the current world.

Women are key maritime stakeholders that provide an important and vital contribution in the maritime domain. Within the framework of maritime development, and through its Women in Maritime programme, under the slogan: “Training-Visibility-Recognition”, IMO continues to support the participation of women in both shore-based and sea-going posts.

IMO maritime training institutions such as the IMO International Maritime Law Institute in Malta as well as the World Maritime University in Malmo also maintain gender balance and train women to be better prepared to pursue their careers in maritime professions. Every year we see more women as naval architects, engineers or maritime lawyers. They are well trained and educated to work shoulder to shoulder with men. IMO supports access to maritime training and employment opportunities for women in the maritime sector.

The Organization is also strongly committed to helping its 175 Member States achieve the UN 2030 Agenda for Sustainable Development and the 17 Sustainable Development Goals (SDGs), particularly Goal 5 “Achieve gender equality and empower all women and girls”.

Considering IMO’s Strategic Direction 6 (Address the human element), the IMO Council Group on Strategic Plan agreed to expand on the various aspects relevant to training, certification and watchkeeping as well as fair treatment, to respond to the current trends and developments such as new technologies, future fuels, bullying and harassment, including sexual assault and sexual harassment (SASH). The work to address sexual harassment at sea will be carried out at IMO in cooperation with ILO. Certainly, more awareness and training in this respect is needed and IMO will continue its efforts to address those matters.

Marek Grzybowski: IMO World Maritime theme for 2023: “MARPOL at 50 – Our commitment goes on”. How has MARPOL changed over these 50 years? What challenges await us in the coming years?

Dorota Lost Sieminska, Director, Legal Affairs and External Relations Division, IMO:

Indeed, 2023 marks the 50th Anniversary of MARPOL, the most important international treaty to prevent pollution from ships into the marine environment. Initially, MARPOL covered accidental and operational oil spills from tankers, the prevention of pollution from chemicals carried in bulk, packaged dangerous goods, sewage, and garbage. Annex VI, which was adopted through the 1997 Protocol, added also the prevention of air pollution from ships.

Over time, the States Parties to MARPOL worked collaboratively to improve the treaty, adopt new requirements to better protect the environment and ensure that all current challenges are addressed. Through five decades, MARPOL has constantly advanced to keep up with lessons learned and new demands. The treaty had a positive impact on the marine environment and has changed how ships are designed and operated. Notably, the number of oil spills reduced by 90%. Thanks to MARPOL, the discharge of plastic garbage into the sea is banned and operational wastes, such as garbage and sewage, cannot simply be disposed of at sea, and are very strictly regulated.

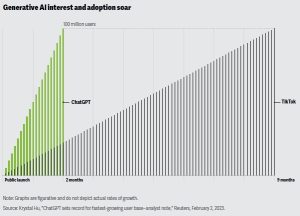

More recently, Annex VI which regulates air pollution introduced new requirements to cut sulphur oxide emissions from ships. Current challenges include addressing the decarbonization of shipping to support the global fight against climate change. IMO is focusing its efforts to enhance sustainable shipping and protect the oceans and populations globally. We must address decarbonization, digitalization and innovative technologies, including automation. At the same time, the seafarers are in the centre of attention and are trained to be well equipped for the technological transition.